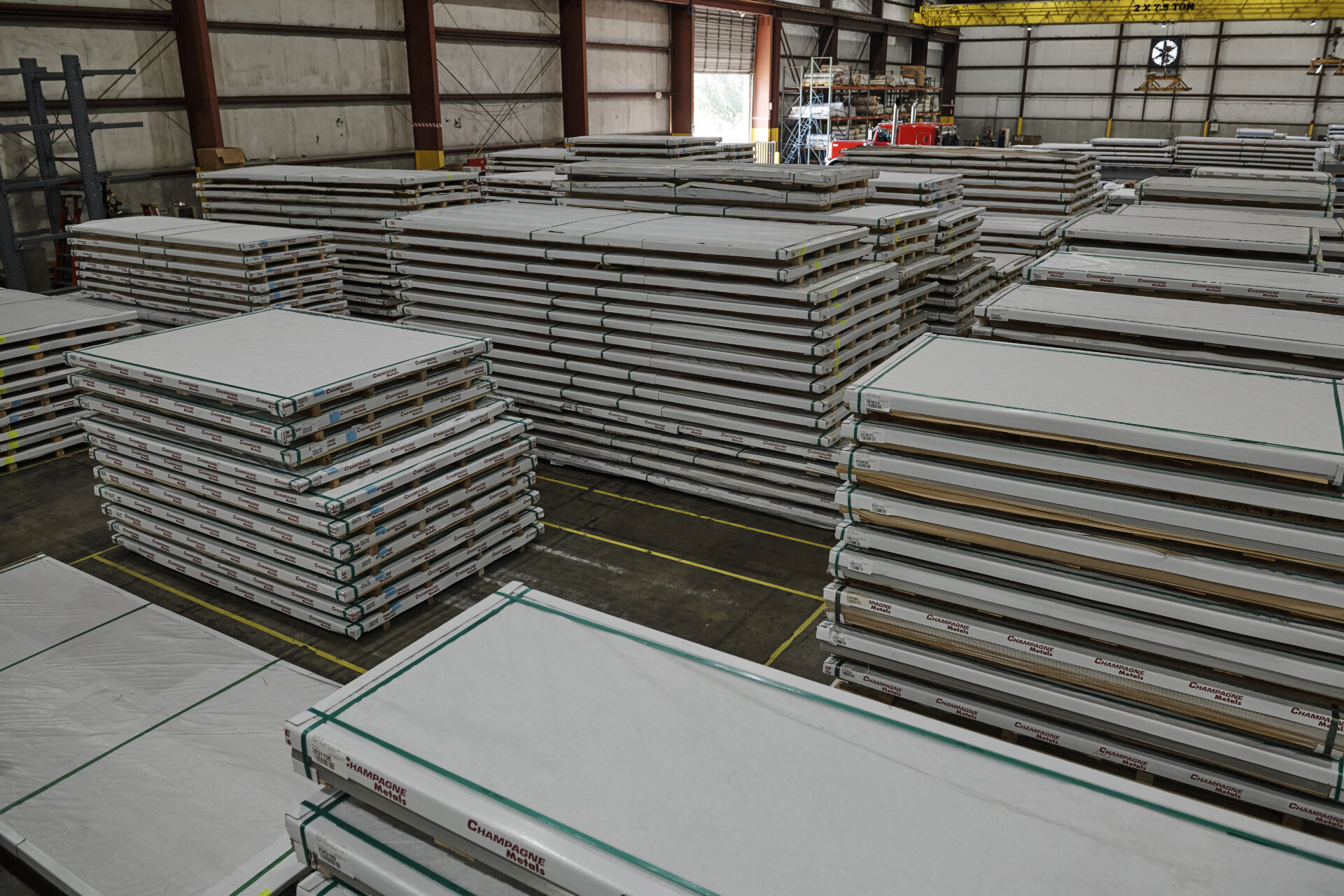

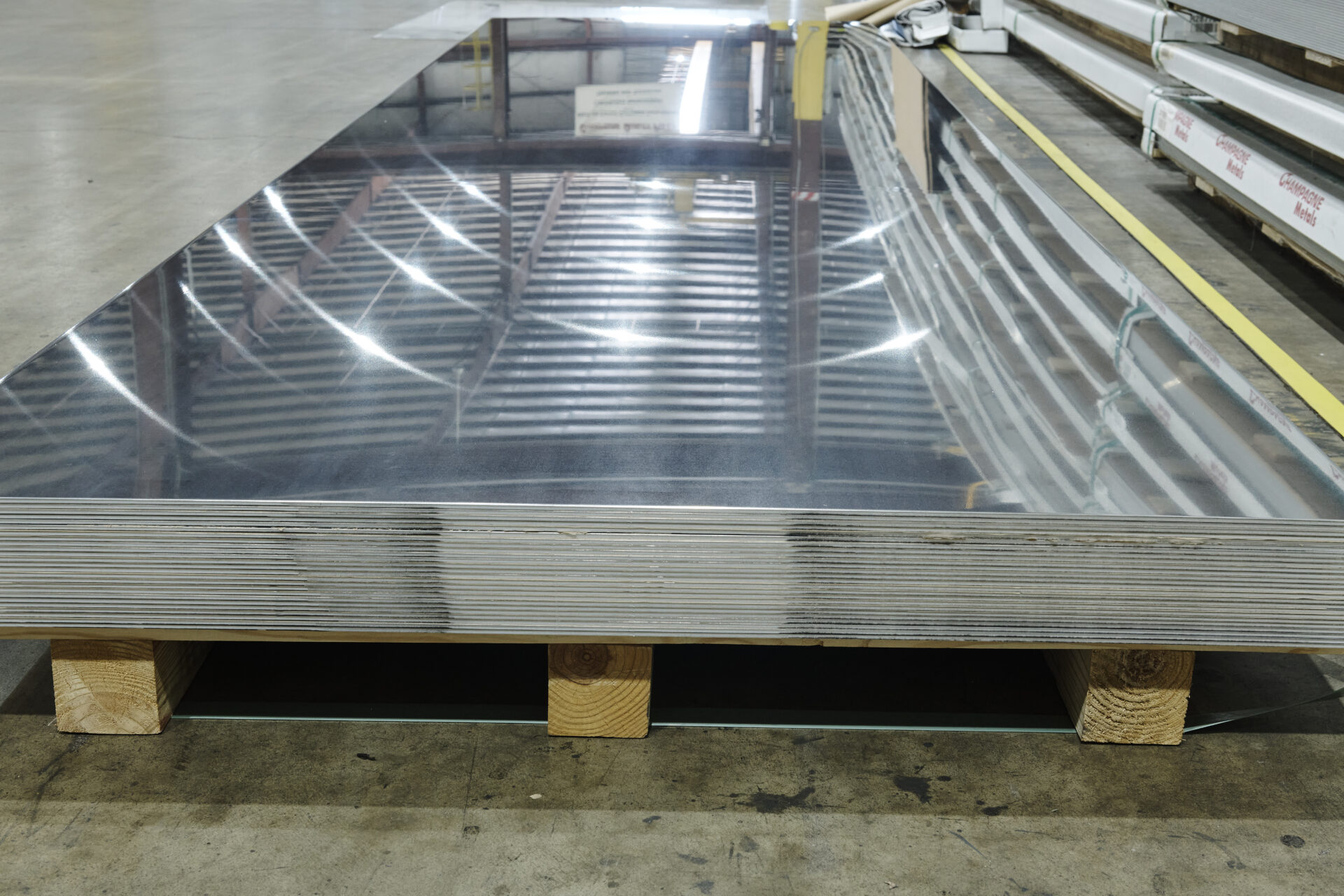

Because of its high strength, low density and excellent corrosion resistance, 5754 sheet aluminum is a popular raw material across various industries. Its ability to withstand water and exceptional weldability makes it an outstanding choice for marine and automotive applications. At Champagne Metals, we work with multiple tempers of 5754 sheet aluminum, including H111.

Request a free quote for 5754 sheet aluminum from Champagne Metals. Our team can help you determine if 5754 is the most practical aluminum grade for your application.

Temper refers to the hardness of a specific alloy. Aluminum 5754 comes in various tempers, and Champagne Metals carries a broad selection in stock. Our experts can walk you through the multiple tempers to help you decide the best option for your requirements.

Several of the most common 5754 aluminum tempers include:

Each temper has varying hardness levels, with O being the softest and H28 the hardest. Champagne Metals has multiple thicknesses and dimensions available.

5754 aluminum sheet alloy contains the following chemical properties:

| SI | FE | MN | MG | CR | Other |

|---|---|---|---|---|---|

| 0.40% | 0.40% | 0.50% | 2.6-3.2% | 0.30% | 0.05% |

The remaining composition is aluminum.

The mechanical properties of 5754 sheet aluminum vary by temper. Tensile strength ranges from 150 megapascals (MPa) for the softer tempers to around 300 MPa for the hardest tempers. Hardness levels, according to the Brinell scale, vary from 44 HB to 87 HB. Champagne Metals can help you choose the ideal temper based on your application’s specifications.

At Champagne Metals, we prioritize superior quality and top-class customer service in everything we do. We stand out from other 5754 aluminum sheet suppliers because of our exceptional technical knowledge and willingness to provide the individualized attention that each customer deserves, regardless of the size of their project or operation. Contact us online today to learn more about how our products and services can benefit your business.