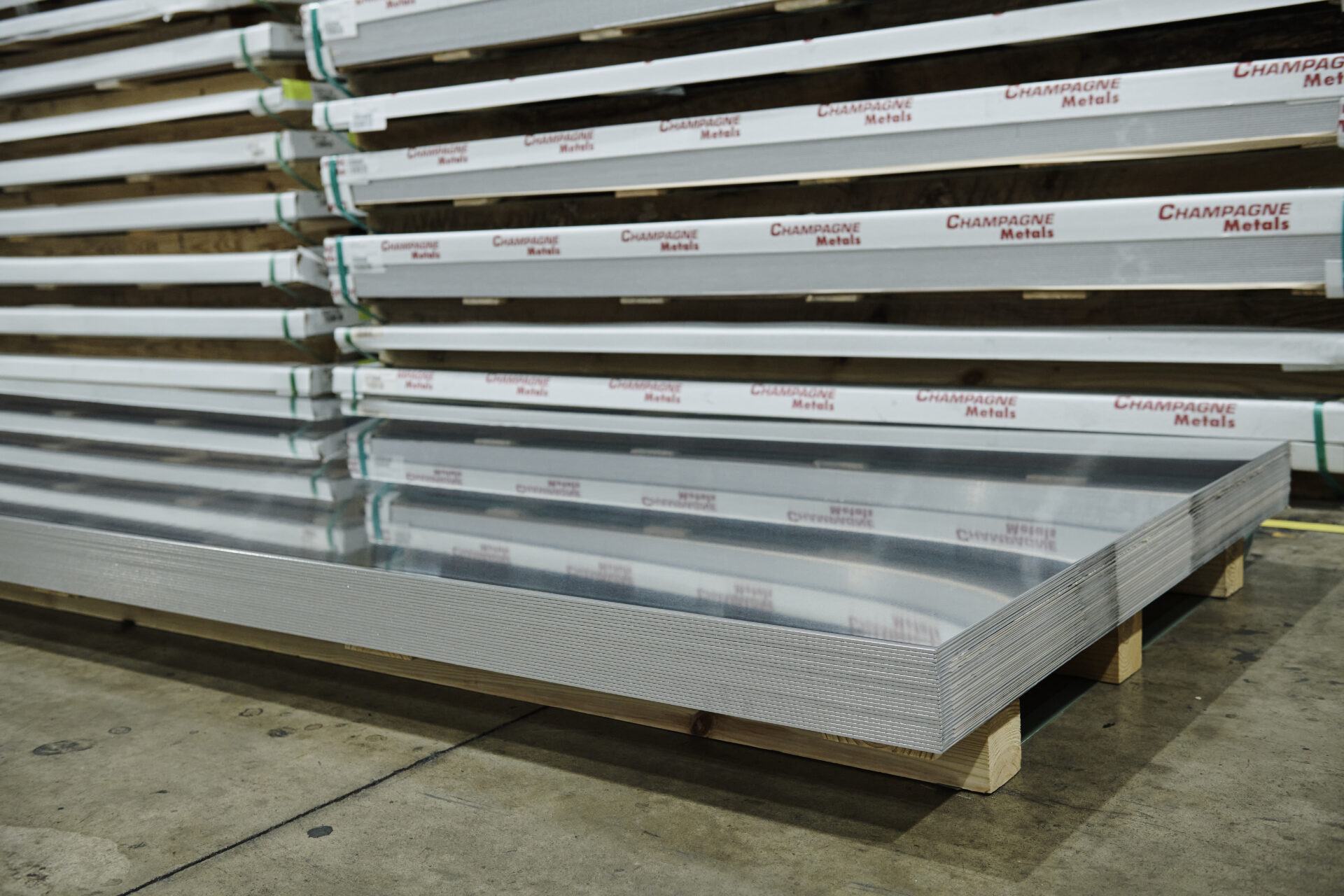

Aluminum sheet 3003 is one of the most in-demand aluminum sheet alloys. It is stronger than 1100 series alloys and reacts well to mechanical finishing. The material has excellent weldability and decent corrosion resistance. Champagne Metals is a producer and distributor of 3003 aluminum sheet. We have multiple locations across North America and work with companies across the continent.

Request a free quote for 3003 aluminum sheet from Champagne Metals. We can help you determine if 3003 sheet is an ideal aluminum grade for your project requirements.

Temper is the hardness of an aluminum alloy. Aluminum 3003 is available in a range of tempers and Champagne Metals has a wide selection in stock. Some of the 3003 tempers we have available include:

Of the tempers, O is the lowest hardness, and H tempers are higher. The number that follows the H determines the hardness, with H24 being harder than H14. An O temper means the aluminum underwent an annealing treatment, which improved its workability, ductility and toughness. H means the alloy was strain hardened at room temperature.

3003 aluminum sheet metal is available in a range of thicknesses and dimensions.

The 3003 alloy contains the following elements:

| SI | FE | CU | MN | ZN | Other |

|---|---|---|---|---|---|

| 0.6% | 0.7% | 0.05-.2% | 1.0-1.5% | 0.1% | 0.05% |

The remainder of the elements in 3003 alloy are aluminum.

The mechanical properties of 3003 series aluminum sheet are based on the metal’s temper. H14 3003 aluminum has a Brinell hardness of 40 and a shear strength of 14,000 pounds per square inch (psi), for example. We can help you choose the right temper based on the mechanical needs of your project.

As 3003 aluminum sheet suppliers, Champagne Metals has a reputation for high quality, exceptional service and dependable delivery. To learn more about 3003 aluminum sheet, contact us today.