Aluminum 5005 primarily contains small volumes of magnesium and manganese in its medium-strength composition, with the number 5005 referring to its alloy composition. It is lightweight and versatile, ideal for applications like the automotive, architecture, signage, packaging, HVAC equipment, construction and transportation industries.

This aluminum type has a smooth surface finish, is corrosion-resistant, has good weldability and is cost-effective in various applications.

Your aluminum needs are specific to your industry and operational requirements. Request a quote and our team will help you decide whether a 5005 aluminum sheet is the best solution to meet your demands.

Aluminum sheet metal tempers contain letters and numbers that indicate the treatment type the alloy has received to obtain the required mechanical properties. Some common 5005 anodized aluminum sheet tempers include:

5005 aluminum’s chemical composition is 97% to 99.5% pure aluminum. Secondary properties include chromium, copper, manganese, iron, magnesium and silicon.

The mechanical properties of aluminum sheet 5005 include hardness, tensile strength and proof stress.

Tensile strength typically ranges from 145 megapascals (MPa) to 185 MPa, while proof stress is 110 Min MPa. The hardness of aluminum sheet 5005 is generally 47 HB according to the Brinell scale.

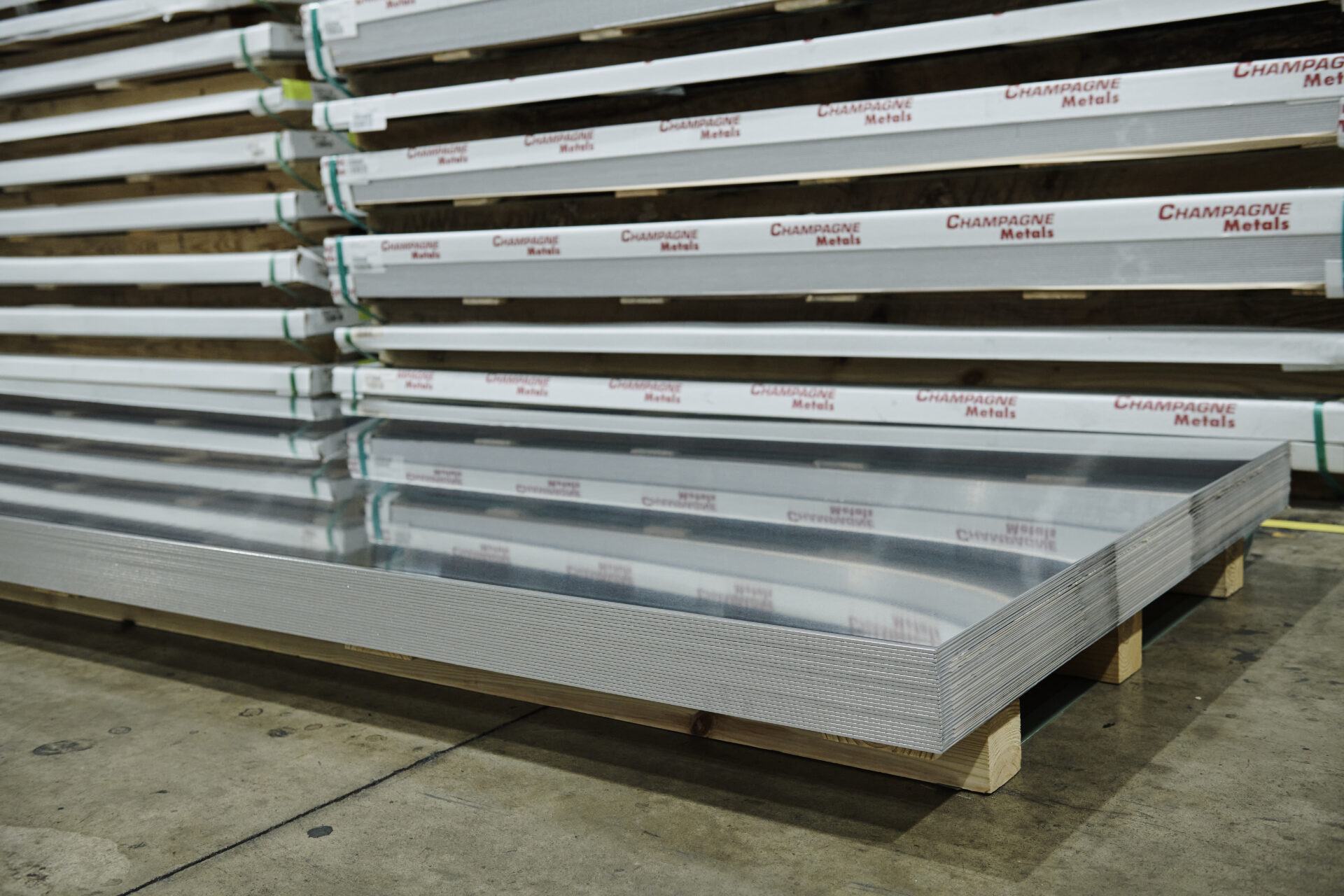

Your individual preferences and needs determine 5005 aluminum sheet’s suitability for your project. We stock it in various thicknesses and sizes so you’ll find exactly what you need. Call us at 888-291-4886 or request a quote on 5005 aluminum or other aluminum types.