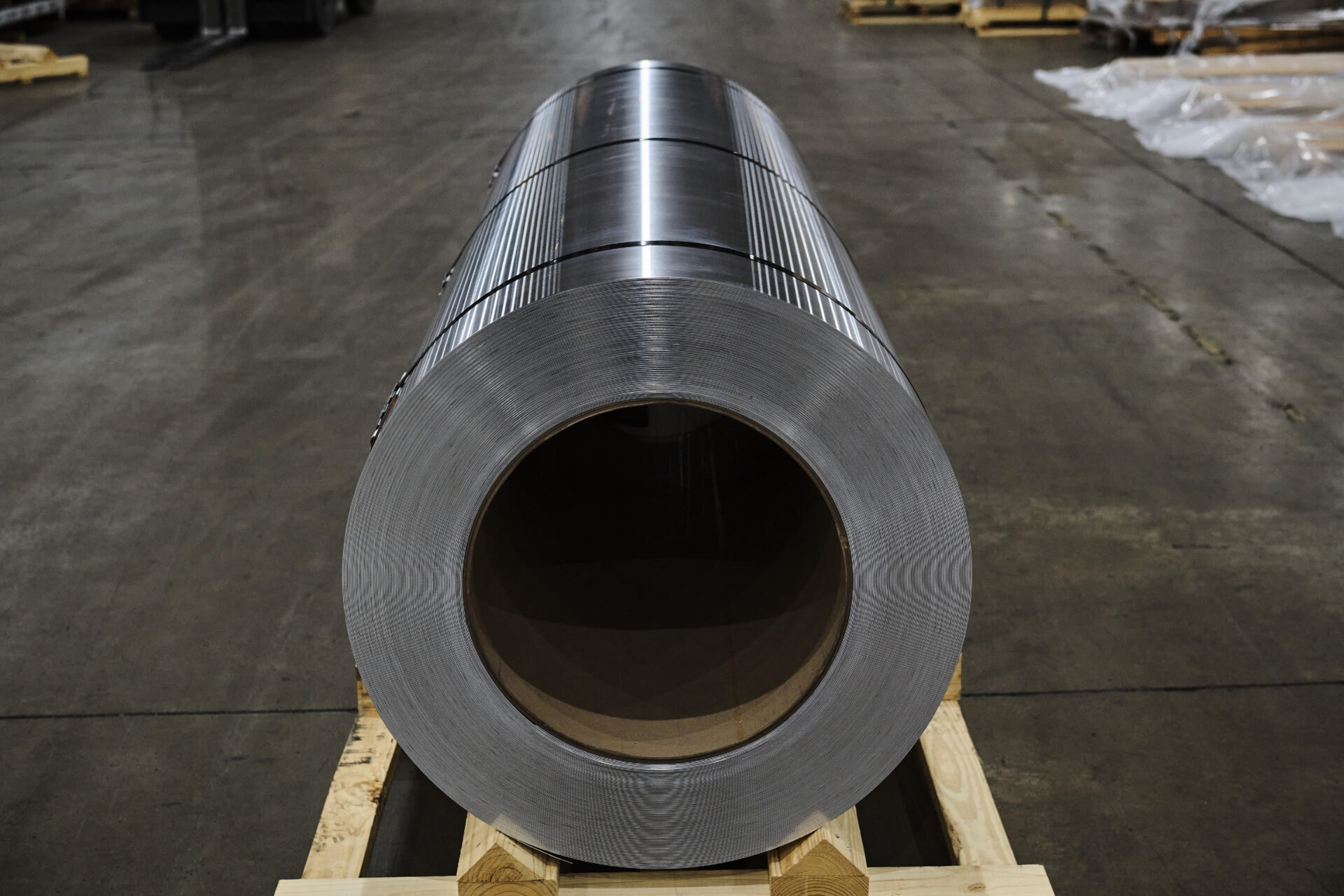

Due to its exceptional formability, aluminum 1100 coil is among the most widely used aluminum alloys, especially in the soft O temper. Since this alloy contains over 99% aluminum, manufacturing and fabrication operations refer to it as pure aluminum. Because of its high versatility and machinability, it works well across a vast application range, from decorative items and electronics to food and beverage containers.

Obtain a quote for aluminum coil 1100 from the experts at Champagne Metals today. Our team can analyze your application to help you choose the most practical size, thickness or temper.

An alloy’s temper refers to the treatment it receives to achieve a desired set of mechanical properties. Several examples of 1100 aluminum coil’s tempers include:

Because of their outstanding formability, O and H14 1100 aluminum coil are among the most common industrial aluminum grades. Coil availability and size options range according to temper.

Aside from several minor traces of iron, copper, silicon and manganese, the chemical composition of 1100 aluminum coil is 99% to 99.9% pure aluminum.

Mechanical properties for 100 coil aluminum vary according to temper. Tensile strength ranges from 110 megapascals (MPa) for the harder tempers to 75 MPa for O temper. Hardness can vary from 23 HB to 28 HB on the Brinell scale.

The experts at Champagne Metals can assess your needs to help you select the optimal temper and coil sizes.

Champagne Metals stands out from other aluminum coil 1100 suppliers with superior product quality backed by top-class customer service. As a family-owned business, we are committed to going above and beyond to provide each customer with the individualized attention they deserve. Contact us online today to learn more about how our solutions can benefit your company.