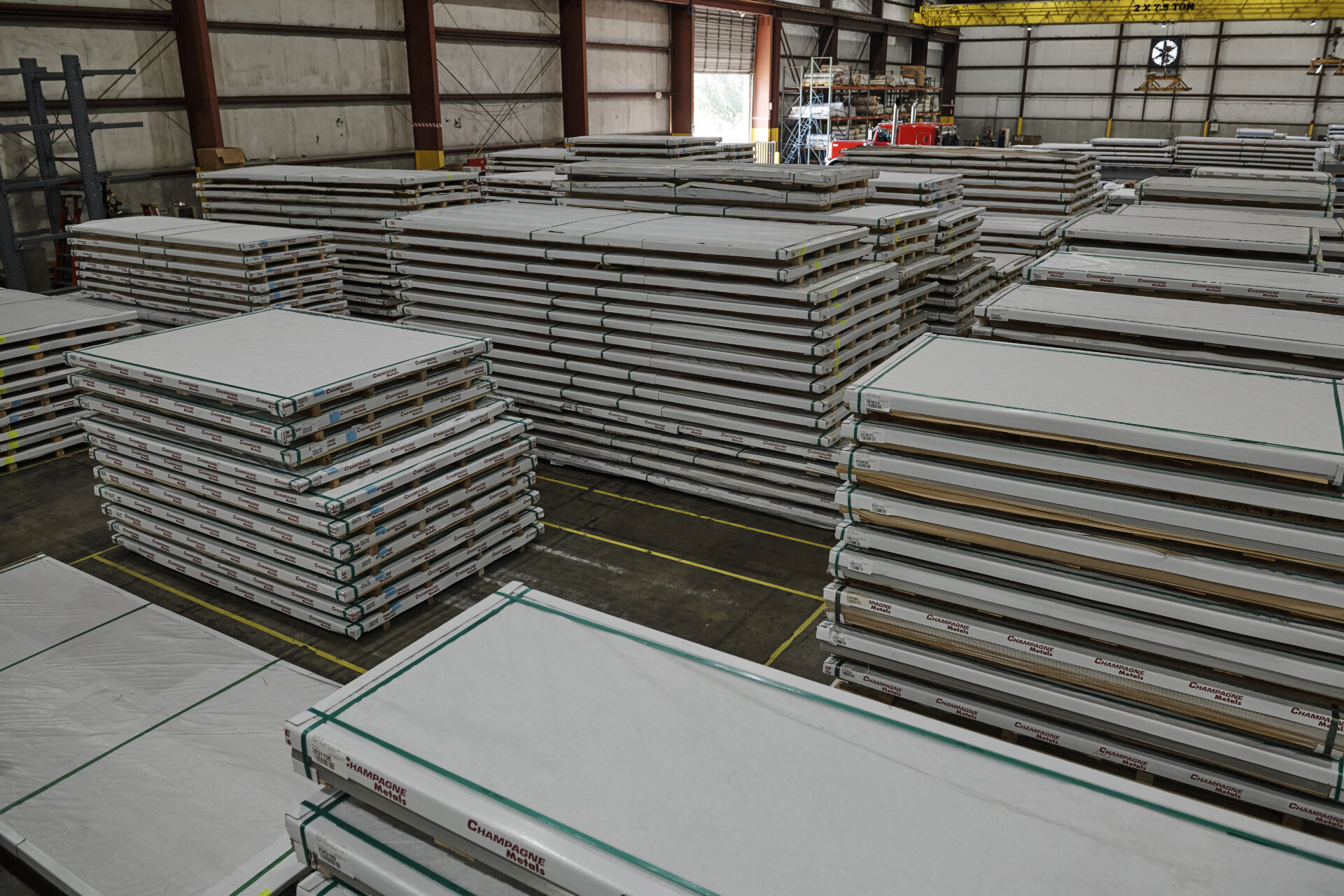

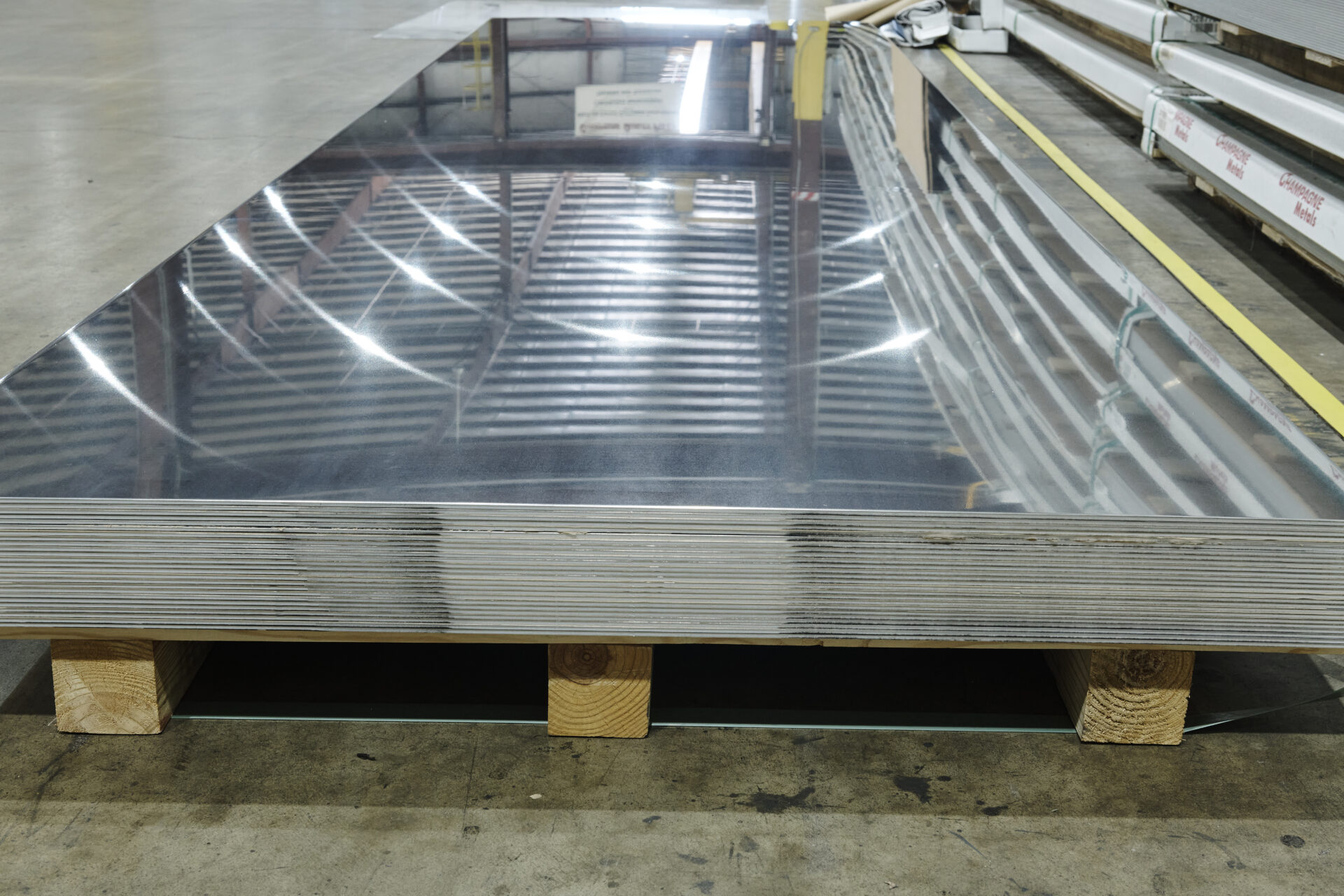

A distinctive feature of 5182 aluminum alloy sheet is the presence of a significant amount of magnesium. The alloy’s magnesium content provides it with excellent corrosion resistance and weldability. Champagne Metals distributes and produces 5182 aluminum sheet for companies across North America. We’re available to answer your questions about the alloy.

Request a free quote for 5182 aluminum sheet from Champagne Metals. We can help you determine if 5182 sheet is an ideal aluminum grade for your needs.

An alloy’s temper refers to its hardness. Aluminum 5182 is available in various tempers, from F to H ratings. F temper alloys are fabricated, while O tempers are made from an annealed metal. When H is used to describe the temper, it means the material is not heat treatable.

The available tempers for 5182 aluminum include:

Aluminum 5182 sheet can be cut into a range of dimensions and thicknesses.

Magnesium makes up a significant part of aluminum 5182’s chemical composition. The elements found in the alloy are:

| SI | FE | CU | MN | MG | CR | ZN | TI | Other |

|---|---|---|---|---|---|---|---|---|

| 0.2% | 0.35% | 0.15% | 0.2-0.5% | 4.0-5.0% | 0.1-0.25% | 0.25% | 0.1% | 0.05% |

The remainder of the chemical composition of 5182 is aluminum.

Hardness, shear strength and other mechanical properties of aluminum 5182 vary based on the metal’s temper. Champagne Metals can help you determine the right temper to choose based on the needs of your application.

Champagne Metals strives to provide dependable delivery, high quality and exceptional service to companies across North America. We’re available to answer your questions or provide you with a 5182 aluminum sheet price quote. Contact us today to learn more.