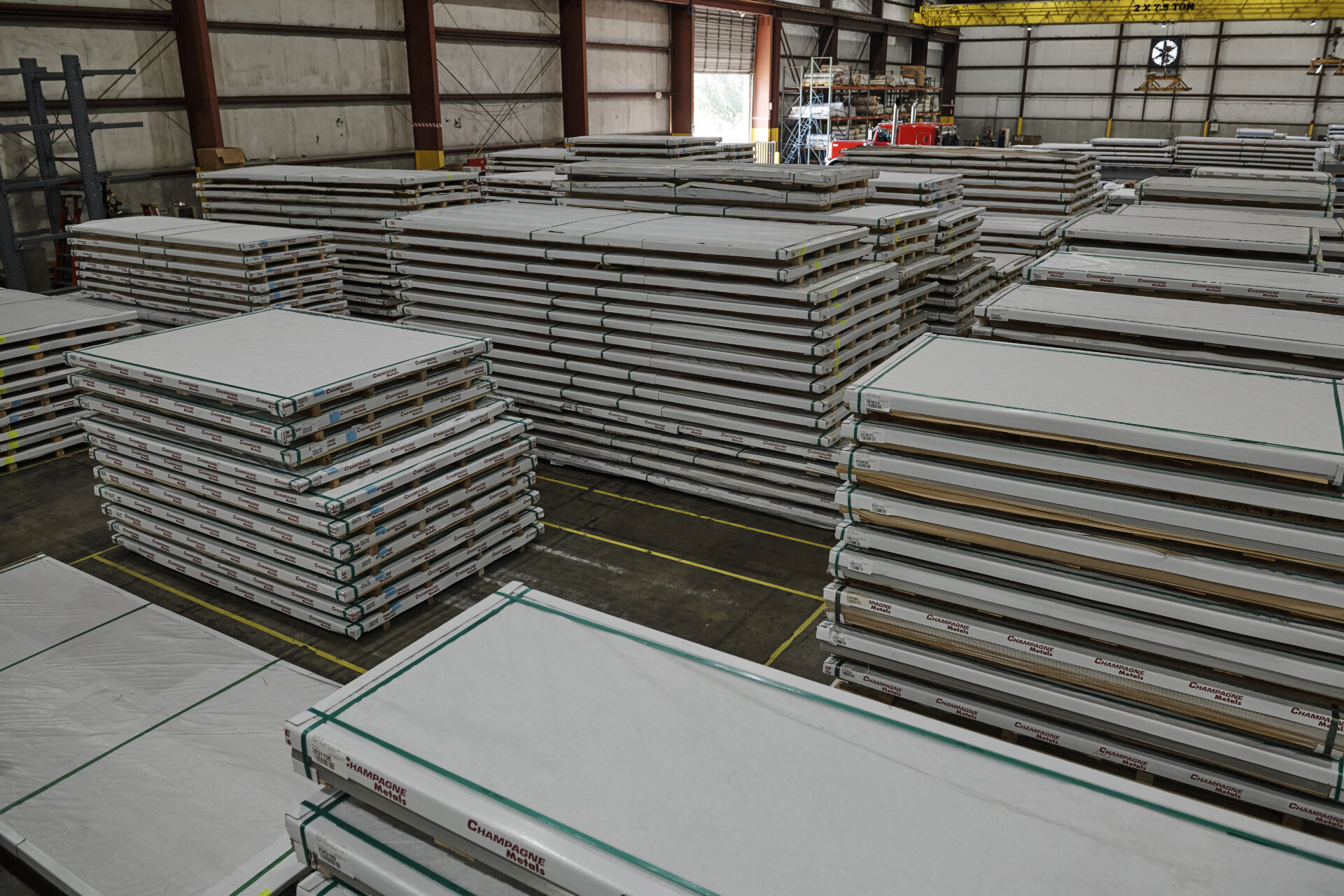

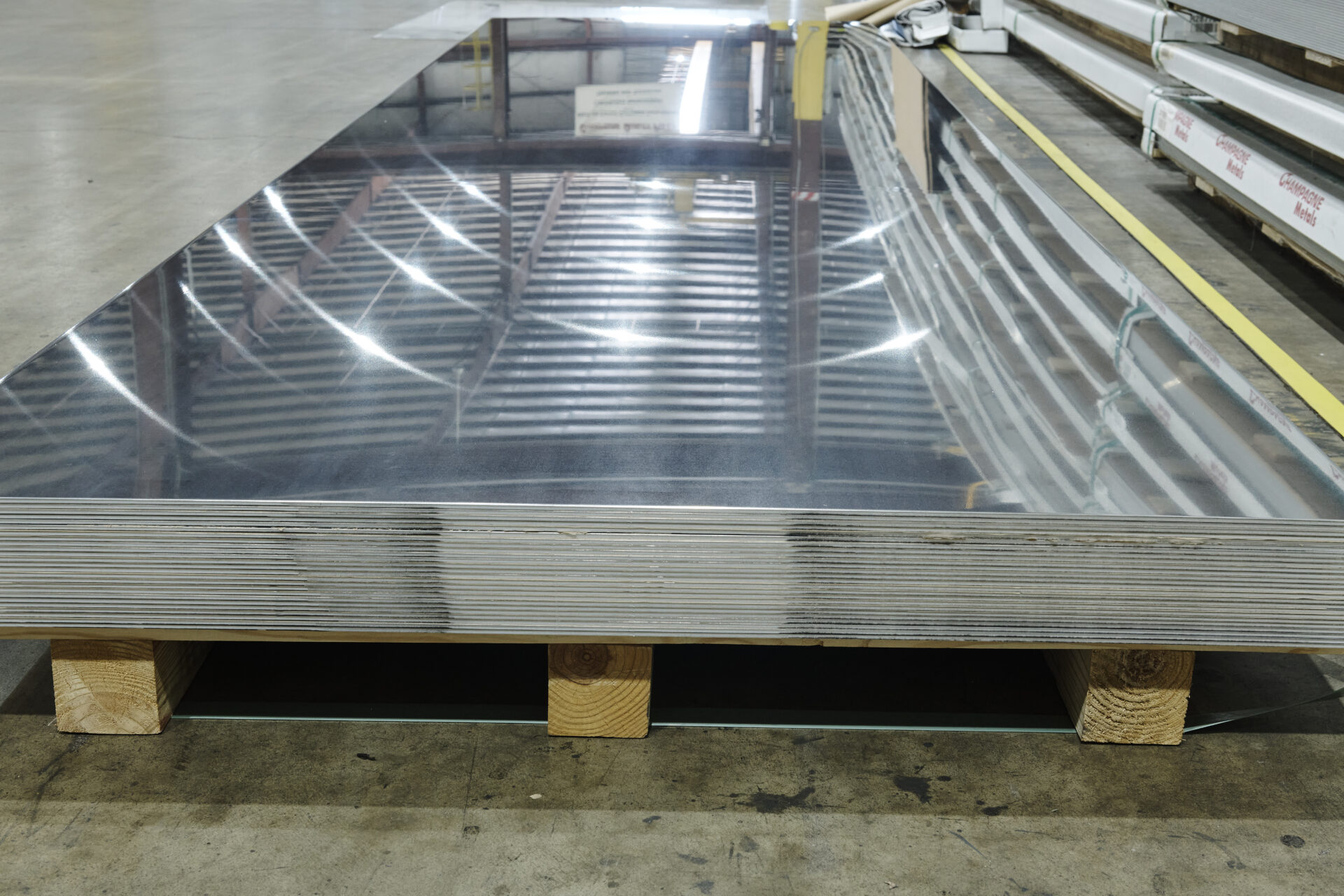

A distinctive feature of 5182 aluminum alloy sheet is the presence of a significant amount of magnesium. The alloy’s magnesium content provides it with excellent corrosion resistance and weldability. Champagne Metals distributes and produces 5182 aluminum sheet for companies across North America. We’re available to answer your questions about the alloy.

Champagne Metals supplies aluminum sheet in various lengths, widths and thicknesses for your fabrication needs. You’ll find that our 5086 aluminum sheet prices are competitive across the market. Our team can furnish a quote or help determine whether 5086 aluminum is a practical fit for your application.

An alloy’s temper refers to the hardening it undergoes to achieve specific mechanical properties. The most popular temper of aluminum 5086 sheet is H32. Other grades include:

O represents the softest temper, while H116 is the hardest. Dimensions vary based on the specific temper you need.

Aluminum 5086 sheet contains the following chemical composition:

| SI | CU | MN | MG | CR | ZN | Other |

|---|---|---|---|---|---|---|

| 0.40% | 0.35% | 0.10% | 0.20-0.70% | 3.5-4.5% | 0.10-0.20% | 0.05-.10% |

The remaining balance is aluminum.

Mechanical properties for 5086 sheet aluminum vary by temper. Tensile strengths range from 250 megapascals (MPa) for O temper to 350 MPa for H116. Hardness can vary from 70 HB to 85 HB according to the Brinell scale.

The experts at Champagne Metals can help you choose the most practical and effective aluminum alloy based on the specific requirements of your project.

At Champagne Metals, we credit superior product quality, exceptional technical expertise and top-class customer service to our decades of successful operation. Our advanced processes and innovative equipment help us exceed customer expectations for each job we complete. Connect with us online to learn more about how our products can benefit your company.