5083 aluminum sheet is widely known across various industries for its superior performance in extreme environments. This alloy exhibits exceptional resistance to seawater and harsh chemicals, making it ideal for automotive, shipbuilding and railway applications. 5083 sheet aluminum has solid overall mechanical properties, including excellent formability and high weldability.

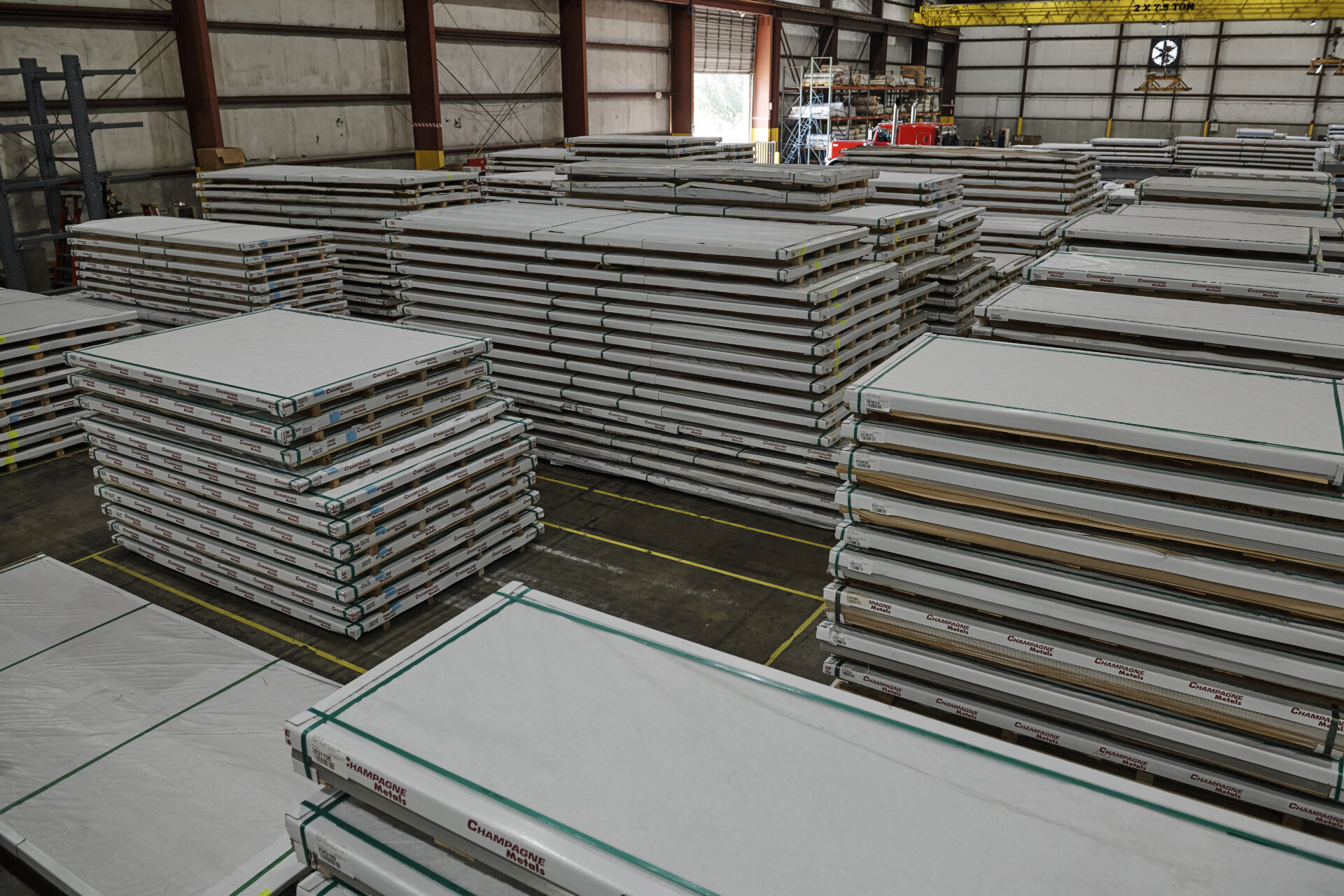

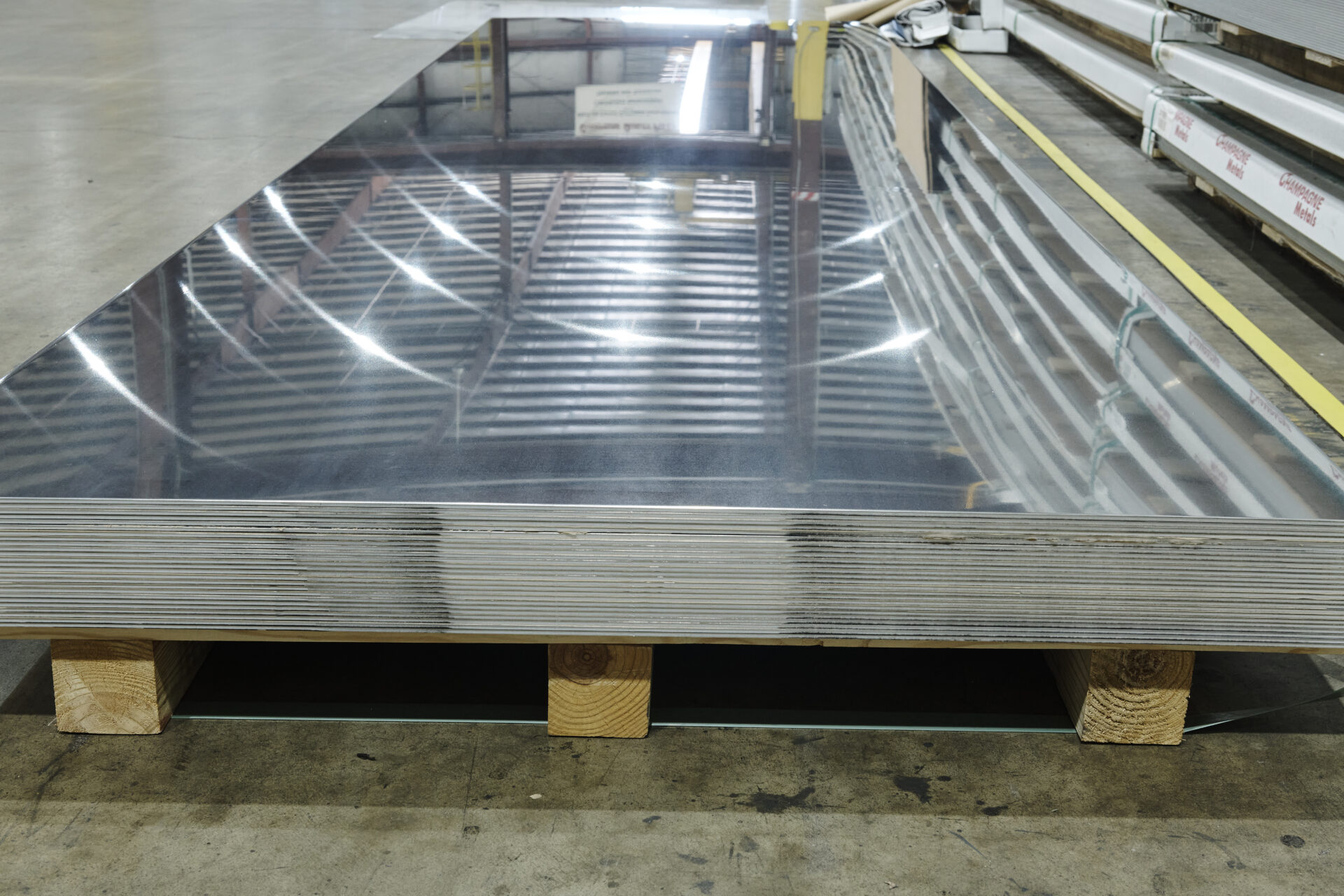

Champagne Metals stocks multiple sizes and thicknesses for your operational needs. Our experts can help you determine whether 5083 is the most practical aluminum alloy for your application.

Temper refers to an aluminum alloy’s condition after treatment to achieve the desired mechanical properties. We stock several of the most popular tempers of 5083 sheet aluminum, including:

Dimensions differ based on the specific temper you choose. Contact our team to determine which size and thickness are best suited for your application’s requirements.

5083 aluminum sheet alloys possess the following chemical properties:

| SI | FE | CU | MN | MG | ZN | TI | Other |

|---|---|---|---|---|---|---|---|

| 0.40% | 0.40% | 0.10% | 0.4-1.0% | 4.0-4.9% | 0.25% | 0.15% | 0.05-.10% |

The remaining composition consists of aluminum.

For 5083 aluminum sheet with O temper, tensile strength ranges from 275 megapascals (MPa) to 300 MPa. The Brinell hardness is 75 HB. For H32 temper, the tensile strength ranges from 305 MPa to 380 MPa, and the Brinell hardness is 89 HB.

At Champagne Metals, we credit top-class customer service, outstanding technical knowledge and superior product quality to our many years of family-run success. Our advanced equipment and innovative processes help us deliver results that exceed expectations for each project we undertake. Contact us online today to learn more about how our solutions can benefit your business.