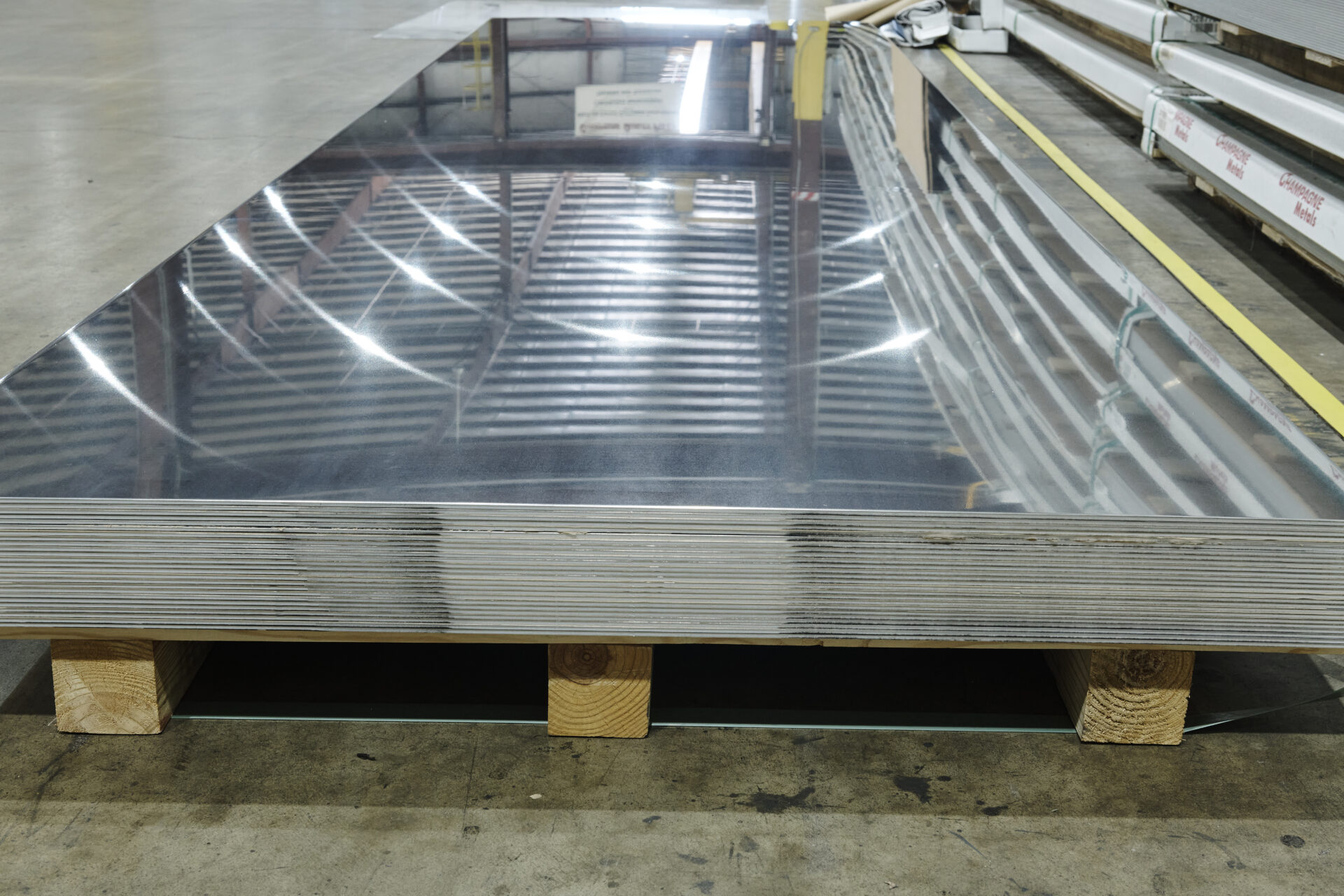

Because it contains a composition of 99% aluminum with minor traces of other elements, industry professionals refer to 1100 sheet aluminum as pure aluminum. Many fabrication and manufacturing operations choose this alloy for its versatility and workability. Aluminum 1100 has an ultra-low density, making it one of the lightest alloys for industrial use.

Request a quote from Champagne Metals based on your operation’s specific needs. Our professionals can help you determine whether 1100 aluminum sheet is the most practical alloy for your requirements.

Aluminum tempers consist of numbers and letters, which indicate the type of treatment the alloy has undergone to achieve the desired mechanical properties. Several of the most common tempers for 1100 aluminum sheet include:

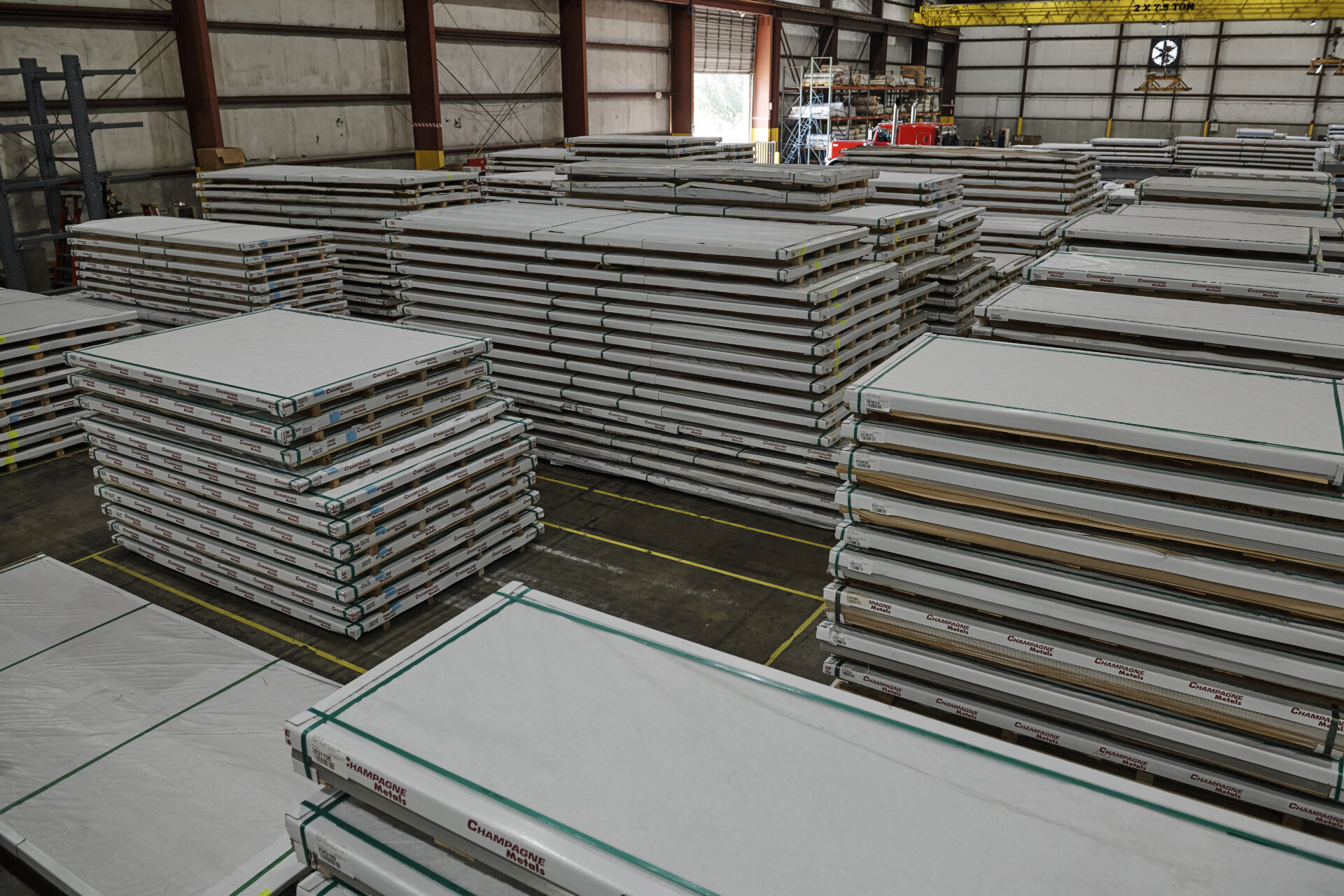

O indicates annealed aluminum and is the softest grade of the alloy. H18 is among the hardest tempers with the highest tensile strength. Champagne Metals stocks various thicknesses and sizes of 1100 sheet aluminum to cover your needs.

The chemical composition of 1100 sheet aluminum is 99% to 99.9% pure aluminum. Minor residuals include copper, iron, manganese and silicon.

Several primary mechanical properties of aluminum sheet 1100 include tensile strength, yield strength and hardness. Typical tensile strength ranges from 75 megapascals (MPa) to 110 MPa, while yield strength varies from 30 MPa to 55 MPa. Hardness is typically 23 HB to 28 HB on the Brinell scale.

If you want to learn more about 1100 sheet aluminum and whether it’s a good fit for your application, the experts at Champagne Metals can guide you. We pride ourselves on superior customer service and exceptional technical knowledge, offering customers across the United States a comprehensive range of aluminum products and processing solutions. Contact us online today for additional information.