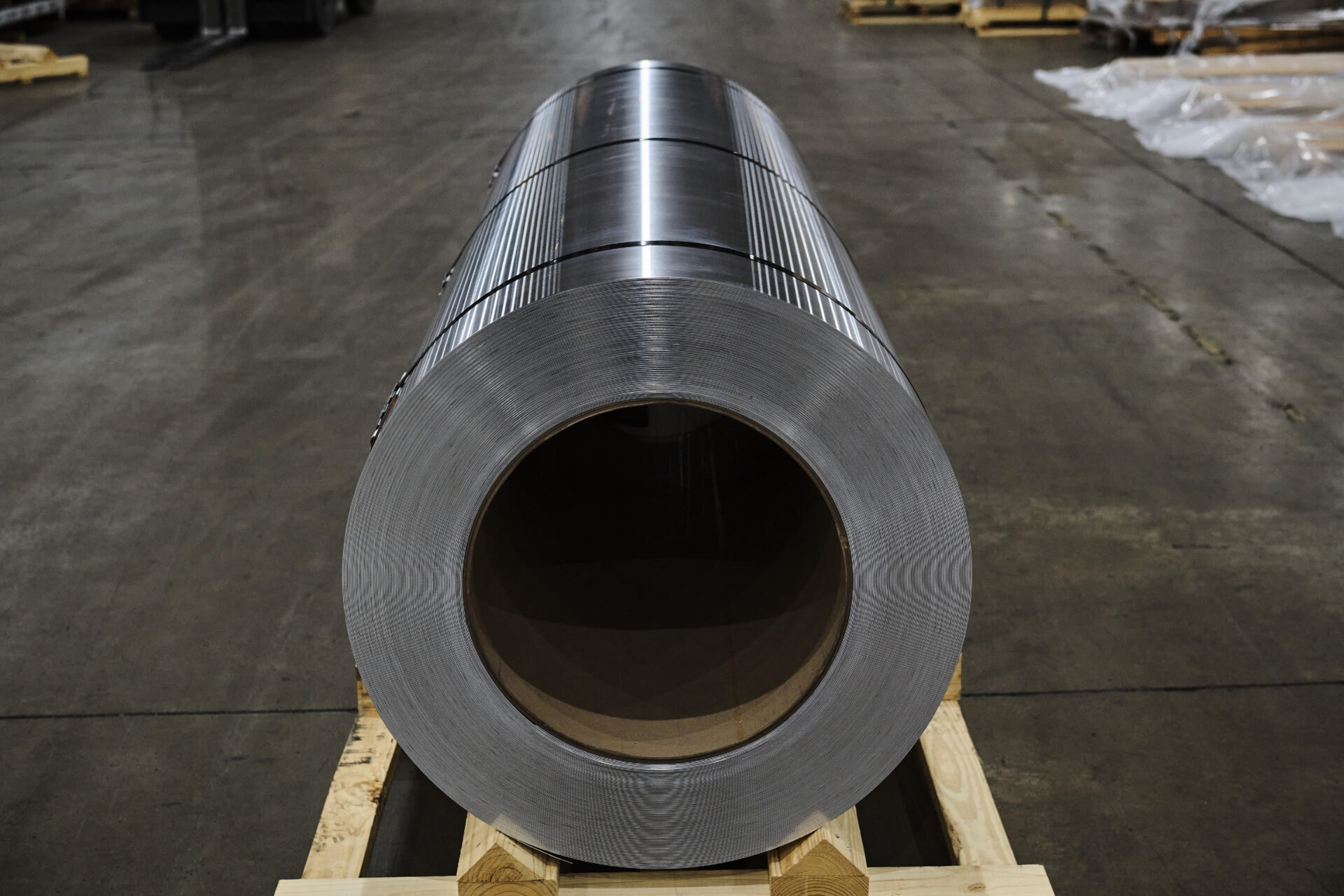

Since 5754 aluminum coil has exceptional workability and high corrosion resistance, it is one of the most common raw materials across a broad application range. As the most popular temper, 5754 H111 aluminum coil dominates the transportation industry, including marine, automotive and railroads. Champagne Metals stocks various grades of aluminum 5754 coil and is one of the top suppliers across North America.

Request a quote for 5754 aluminum coil from the professionals at Champagne Metals. Please continue reading to learn more about this popular alloy and whether it is a practical choice for your operation.

Aluminum temper designations indicate how an alloy has been mechanically treated to achieve the desired properties. Some of the most well-known tempers for aluminum 5754 coil include:

H28 represents the highest hardness level for 5754 aluminum coil, while O is the softest. Champagne Metals offers a broad selection of tempers, sizes and thicknesses.

The majority of the chemical composition of aluminum coil 5754 is aluminum. The remainder includes:

| MG | SI | FE | CR | MN | Other |

|---|---|---|---|---|---|

| 2.60-3.20% | 0.40% | 0.40% | 0.30% | 0.50% | 0.05% |

Production processes can introduce some differences, leading to minor property variations.

Several critical mechanical properties of 5754 aluminum coil are tensile strength and hardness. Typical tensile strength can range from 150 megapascals (MPa) to 300 MPa, depending on the temper. Hardness levels can vary from 44 HB to 87 HB on the Brinell scale. When you contact Champagne Metals, our experts can help you determine the optimal alloy and best mechanical properties for your specifications.

As a family-owned company, Champagne Metals is committed to providing top-class customer service and exceeding your expectations for each project. With multiple locations across the United States, we can serve customers throughout North America. Contact us online today for a quote or to request additional information.