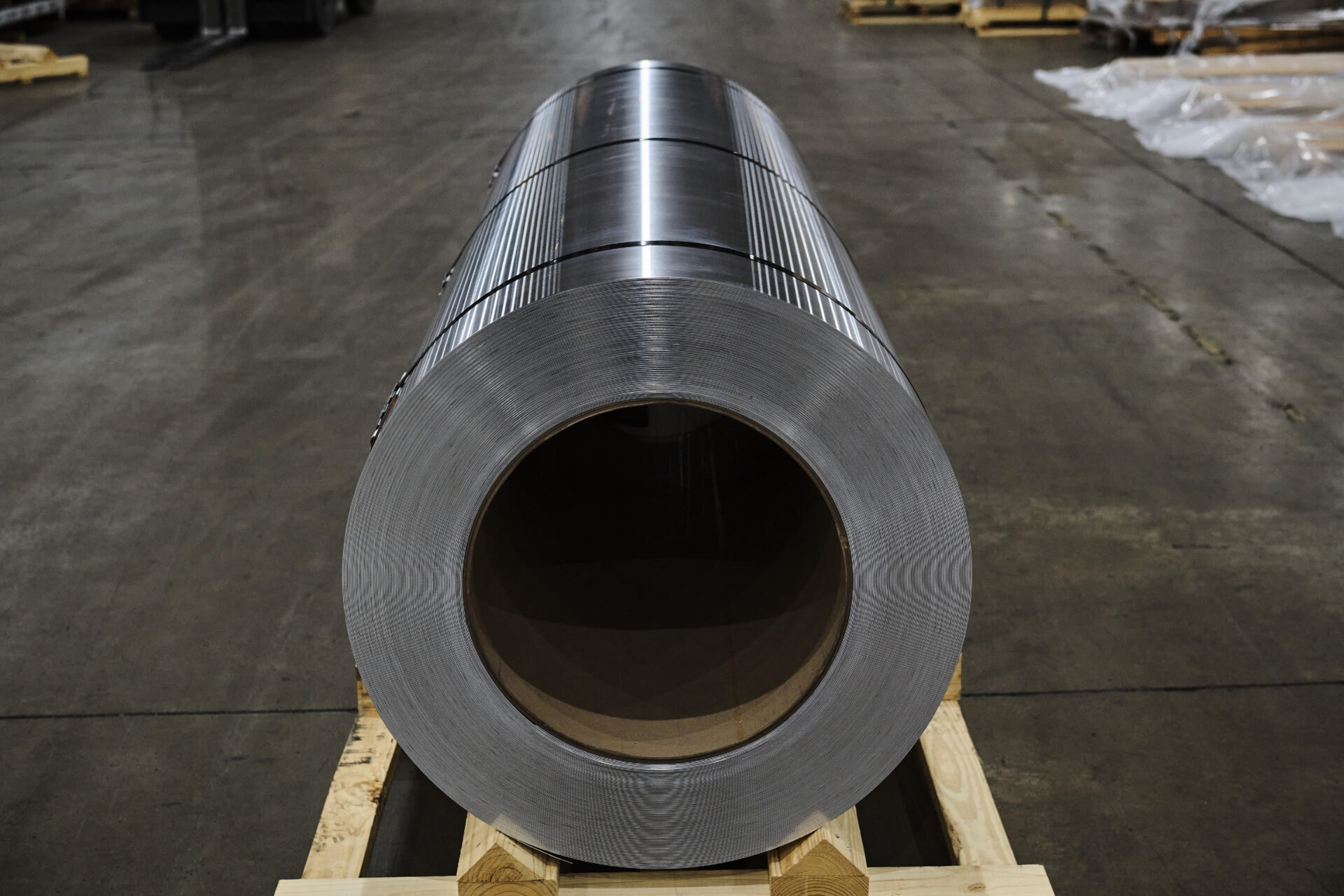

As a 5182 aluminum coil processor and distributor, Champagne Metals is committed to providing high-quality aluminum products and excellent customer service.

Aluminum coil 5182 has good weldability and corrosion resistance and is generally representative of medium-strength aluminum alloys. It has multiple applications, particularly in the construction industry. It’s also the aluminum alloy most commonly used in beverage cans.

Request a free quote for 5182 aluminum coil from Champagne Metals. We can help you determine if 5182 coil is an ideal aluminum coil grade for your needs.

The temper options for 5182 aluminum coil include:

Thicknesses range from 0.2 to 8 mm, depending on the application. Width ranges from 6.365 to 1524 mm, and length options range from 305 to 3,657.6 mm. We can help you decide which size is best for your application.

As an alloy, aluminum coil 5182 consists of aluminum combined with several other metals. The primary alloy element is magnesium. The chemical properties of aluminum 5182 are:

| MG | SI | FE | CU | CR | ZN | TI | MN | Other |

|---|---|---|---|---|---|---|---|---|

| 4.00-5.00% | 0.20% | 0.35% | 0.15% | 0.10-0.25% | 0.25% | 0.10% | 0.20-.50% | 0.05% |

Aluminum coil 5182’s mechanical properties vary by temper. Champagne Metals can help you decide which tempers align with your mechanical property requirements.

Champagne Metals is a North American aluminum processor and distributor. As a family-owned company, we’re committed to exceeding your expectations.

For more information about 5182 aluminum coil or to get a quote, contact us today.