5086 aluminum coil is a versatile alloy widely known for its exceptional corrosion resistance in seawater applications. Although it is not heat-treatable, it can be cold-worked to increase strength across various temper grades. The high weldability and moderate strength of 5086 coil aluminum make it ideal for the marine and automotive industries.

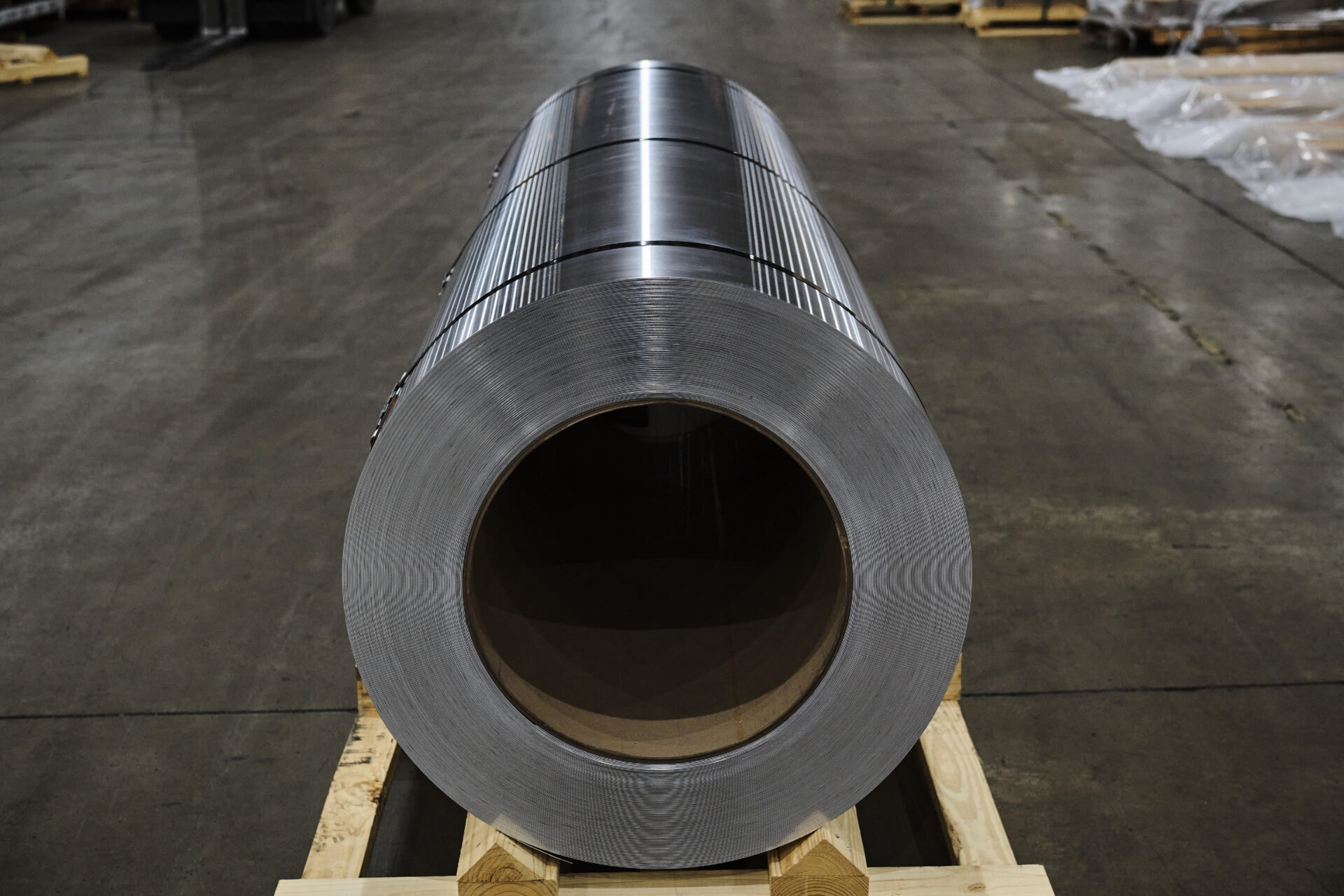

As a leading supplier of various aluminum alloy sheet and coil, Champagne Metals stocks a range of 5086 aluminum coil sizes to meet your operational requirements. Obtain a free quote from our expert team today.

An alloy’s temper designation indicates how the metal was treated to achieve the desired mechanical properties. Aluminum 5086 coil has various tempers like H32 that are common for industrial use. Examples include:

H116 indicates the hardest and strongest temper, while O represents the softest. Coil sizes and availability vary by temper.

The majority of the chemical composition of 5086 aluminum coil is aluminum. The balance includes:

| MG | SI | ZN | CR | MN | CU | Other |

|---|---|---|---|---|---|---|

| 3.50-4.50% | 0.40% | 0.25% | 0.10-0.20% | 0.20-.70% | 0.10% | 0.05% |

The mechanical properties of 5086 aluminum coil depend on the specific temper. Tensile strength varies from 350 megapascals (MPa) for H116 temper to 250 MPa for softer O tempers. According to the Brinell scale, hardness ranges from 70 HB to 85 HB.

The professionals at Champagne Metals can help assess your specific needs to choose an optimal alloy.

If you want to learn more about 5086 aluminum coil and whether it’s a practical choice for your requirements, the professionals at Champagne Metals can assist you. As a family-owned company, we have leveraged decades of superior product quality backed by top-class customer service to become a leading aluminum supplier. Contact us online today for a quote or additional product information.