Because of its superior corrosion resistance, 5083 aluminum coil is prevalent in applications that need high protection in harsh environments — including components for the marine and automotive industries. Since many aluminum 5083 coil tempers possess low density and high tensile strength, this alloy is perfect for manufacturing operations requiring durable materials for lightweight construction. In addition, 5083 aluminum is compatible with most metal fabrication and welding techniques.

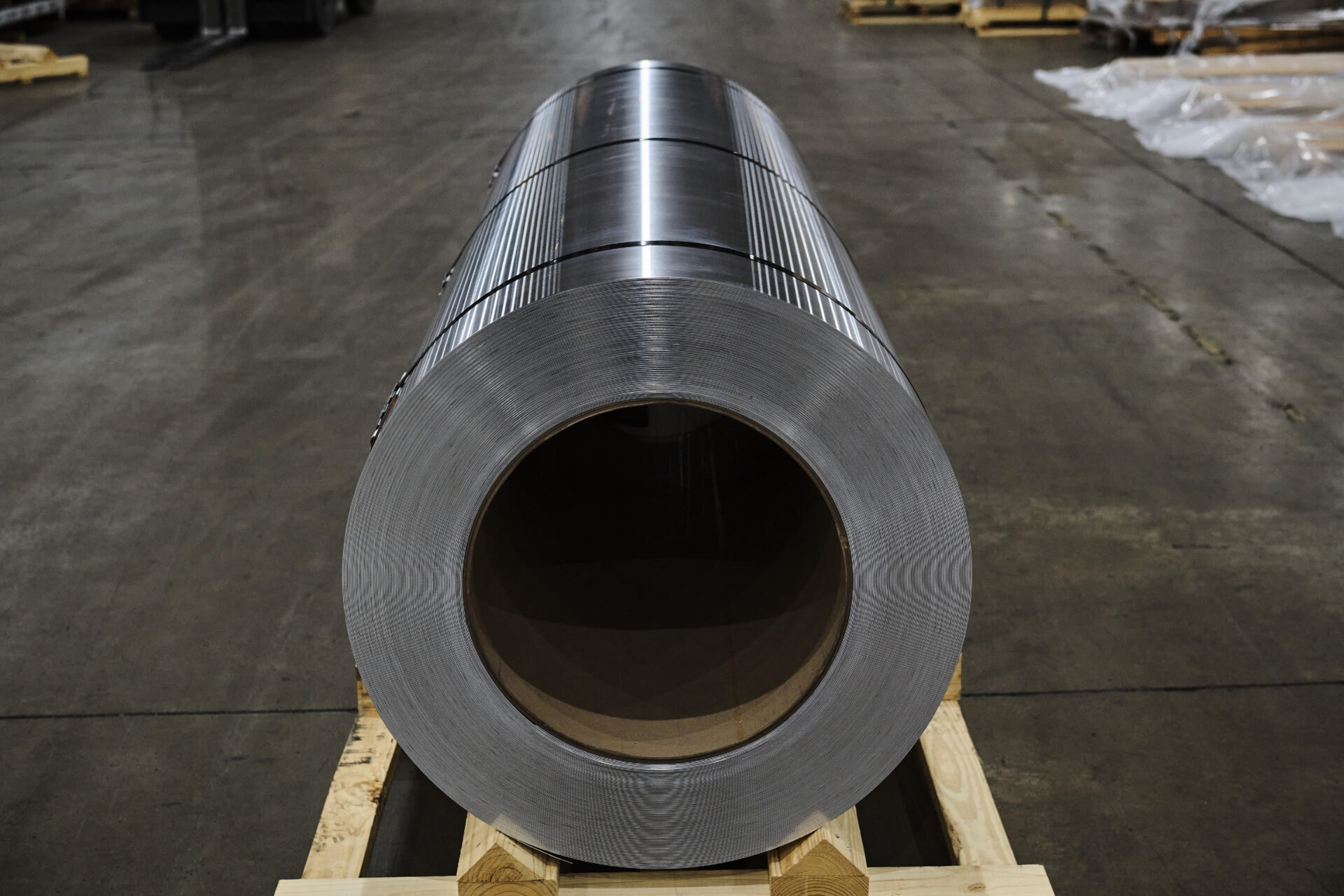

At Champagne Metals, we stock an extensive selection of 5083 aluminum coil sizes, tempers and thicknesses. Request a quote today based on your operation’s specific needs.

The temper designation refers to the mechanical treatment an alloy receives to achieve a desired set of properties. Among the most common tempers of 5083 aluminum coil are:

Available thicknesses and sizes vary according to tempers. Our experts can help you choose the most practical temper and size based on your requirements.

The majority of 5083 coil aluminum’s chemical composition consists of pure aluminum. Minor traces of several other elements are present, including:

| SI | CU | FE | MG | MN | TI | ZI | Other |

|---|---|---|---|---|---|---|---|

| 0.40% | 0.10% | 0.40% | 4.0-4.9% | 0.40-1.0% | 0.15% | 0.25% | 0.05-0.10% |

Percentages can vary slightly by temper.

Mechanical properties for aluminum 5083 coil differ according to the specific temper. Tensile strength ranges from 275 megapascals (MPa) for softer tempers to over 300 MPa for stronger tempers. Hardness varies from 75 HB to 90 HB according to the Brinell scale.

If you’re looking for a reliable 5083 aluminum coil supplier that delivers superior product quality, Champagne Metals is the perfect choice. As a family-owned business, we understand that individual attention and outstanding customer service are essential for establishing long-lasting relationships. Connect with our experts today to learn more about how our products and services can help your operation succeed.