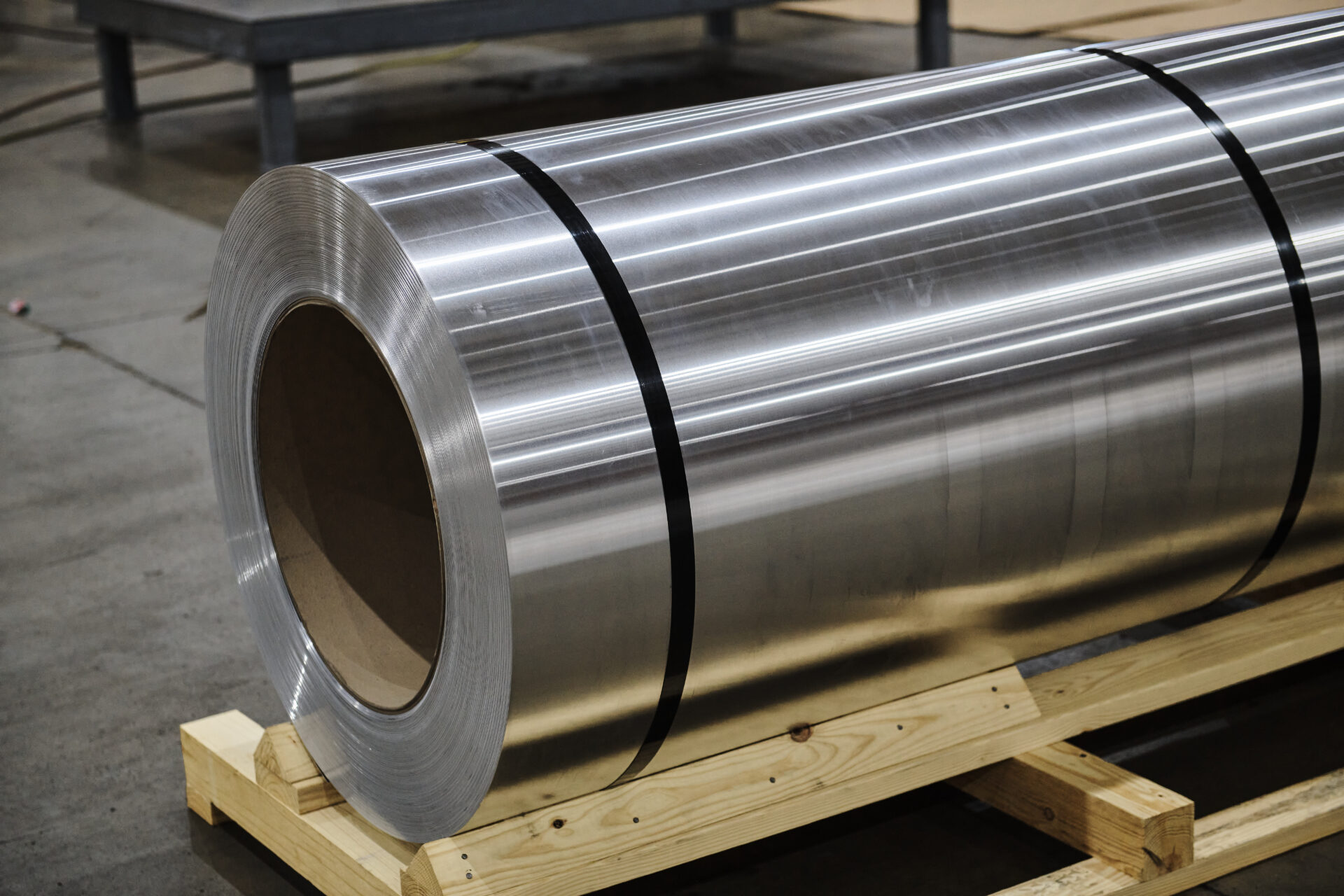

Along with sheet, 5005 aluminum alloy is also available in coil and is commonly used decoratively and architecturally. It resists aerial corrosion, achieves elevated strength through cold working and has high weldability. It is versatile and used in numerous applications like the automotive and shipbuilding industries.

Enquire about our 5005 aluminum coil supply, and we’ll advise you on the ideal temper, size and thickness to suit your application’s needs.

Temper relates to an alloy’s treatment to acquire the necessary mechanical properties. Since 5005 aluminum coil is essentially rolled up 5005 aluminum sheet during production, both types have similar tempers. These are some common 5005 aluminum coil tempers:

The chemical composition of 5005 aluminum coil is 97% to 99.5% pure aluminum, with minimal traces of chromium, copper, iron, manganese, silicon and magnesium.

Temper affects the mechanical properties of 5005 aluminum coil, ranging in variation. The coil is measured by proof stress, tensile strength and hardness. The proof stress of 5005 aluminum coil has a minimum megapascal (MPa) rating of 110, offering optimal endurance. Its tensile strength ranges between 145 MPa and 185 MPa, and the Brinell scale places its hardness at 47 HB.

If you’re uncertain which temper and coil size is suitable, our expert team will guide you through our available stock to find what you need.

Champagne Metals understands your unique requirements and adheres to stringent quality standards to deliver the best products. We are committed to providing superior customer service, going above and beyond in every interaction. You can expect our aluminum coil to be delivered on time with our dependable services available throughout North America.

If you’re looking for more than 5005 aluminum coil, we have an extensive selection of aluminum sheet, coil and plate for various applications. Call us at 888-291-4886 or request more information by completing this form today.